When augmented reality (AR) headsets from major tech companies became available a few years ago, there was a great flurry of activity around finding applications, particularly in the manufacturing space.

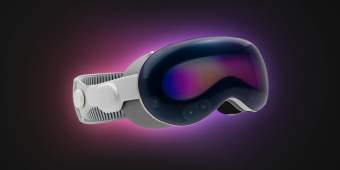

A few years on, however, AR hasn’t caught on in most industrial environments. Still, when Apple launched its Vision Pro earlier this year, touting new “spatial computing” capabilities, we decided to test the device for ourselves. Our take: this isn’t just AR with a facelift.

In fact, spatial computing can have profound impacts on manufacturing operations. Here’s a look at why—and what makes it so different from the AR of a few years back.

AR in manufacturing: A solution in search of a problem

First, let’s clarify some terms.

Both spatial computing and AR are considered “extended reality,” which is often used as an umbrella term to describe any kind of digital overlay onto the real world. But there are important distinctions between different types of physical-digital collaborations:

Virtual reality creates fully immersive experiences you can interact with. It typically requires a headset that covers your eyes so that what you see is not physically present.

Augmented reality involves virtual objects being overlaid onto the physical world in real time. Social media filters are a familiar example. You don’t necessarily need dedicated hardware, but there are types of headsets that create AR experiences.

Mixed reality brings the physical and virtual worlds together. You could pick up a virtual piece of toast with your physical hand, for example. The metaverse promises mixed reality experiences.

When first-gen AR and VR headsets like the Meta Quest and the Oculus Rift came to market, some in the manufacturing space saw the potential for factory-floor AR applications. After all, these devices made it possible to project digital information onto the real world—i.e., to augment reality.

In theory, the applications for manufacturing seemed endless: workers on the floor could use computer vision to project assembly instructions onto parts in front of them, for example, or turbo-charge their ability to spot defects on a QA line. They might even do simulations of product assembly or machine operation.

In reality, though, those applications fell flat for several reasons:

AR headsets can be heavy. For workers whose jobs are already physical, adding additional weight can increase strain on the body and make injuries more likely.

Sometimes, the headset design interfered with necessary personal protective equipment (goggles, helmets, etc.).

Temperatures in manufacturing facilities can vary widely—from sub-freezing to steamy hot. While most headsets are fine in hot or cold environments, they don’t function well at extremes..

Many AR applications rely on voice or gesture commands, but manufacturing facilities can be noisy. Workers may also be wearing PPE that obscures their faces or hands, which can interfere with the headset's function.

Finally, AR is a new technology for the majority of workers. Adopting new tech is difficult at the best of times; when a device already has notable shortcomings getting workers to adopt it can be impossible.

So while the theory of AR in manufacturing was compelling, its reality was disappointing.

Spatial computing is fundamentally different.

What's different about spatial computing

First, let’s acknowledge the ways spatial computing is like AR: both involve both physical and digital objects that exist within the physical world. Both can be accessed via a headset or smart glasses (though AR, as we noted, doesn’t always require specialized equipment). And both aim to provide greater depth of understanding or functionality for things in the real world (versus VR, which is more about existing in a purely digital world).

But while AR is more about enhancing your real-world environment in a purely visual way—that is, creating a user experience that shows physical surroundings with some digital objects added in —spatial computing is more of a framework where digital and physical elements interact dynamically, across multiple sensory modalities and input methods.

In spatial computing, the physical location may be incidental to the digital content a user is grappling with, whereas in AR, digital objects and other virtual elements serve to enhance a specific physical reality.

Now, to home in on the manufacturing use case: If the main (theoretical) function of AR in manufacturing was to overlay digital displays on physical reality, the main function of spatial computing (as of right now) is to experience data in three dimensions.

As you can imagine, that changes the conversation about how and where to apply this immersive technology in a manufacturing setting: rather than focusing on the factory floor, we’re now looking at what's possible for workers who currently spend a lot of time in labs, offices, or any physical space that requires significant data analysis.

Example use case: imagine a new composite material made from plastic trash removed from waterways. You’re a manufacturer trying to determine whether you might be able to swap out existing material inputs for this replacement—and address some of your Scope 3 emissions in the process.

Rather than poring over specs on endless two-dimensional graphs and charts, spatial computing would let you experience those specs—hardness, elasticity, melting point, etc.—in three dimensions, so you might more easily compare them with established parameters.

In the digital world made possible via spatial computing, you could more quickly determine whether the material is a viable alternative, and more easily calculate what other specs might need to change to accommodate it.

3 spatial computing applications that will change manufacturing

For now, Apple’s Vision Pro doesn’t fully solve the problems that AR headsets had for workers on the factory floor. It’s heavier than Microsoft’s Hololens, for one thing—the single biggest drawback of the device at this point (and something we expect to get better in future models).

But its enhanced capabilities in other realms—higher-resolution digital displays, high-performance hardware for rendering complex and high-resolution 3D objects, controller-less interactions using hand and eye tracking, and a dedicated machine learning chip (CoreML) among them—mean it’s a device to take seriously in the manufacturing industry as a whole.

Among the immediately viable applications we’re most excited about:

Safer training environments. Because of the Vision Pro’s extremely high-definition display, virtual environments it creates feel real. As we’ve mentioned elsewhere, this has huge implications for training workers to do dangerous tasks or work in dangerous environments.

Faster root cause / failure analysis. RCFA is complex, data-intensive work. Spatial computing makes it possible to consider data in three dimensions, making it easier to make connections, see associations, and complete RCFA.

Easier supply chain management. Supply chains are among the most complex systems in all of manufacturing. By making it possible to interact with supply chain data in three dimensions, spatial computing makes the work of supply chain management more tangible and therefore facilitates decision-making. The difference between two-dimensional and three-dimensional data representations is akin to the difference between looking at a spreadsheet of numbers and looking at interfaces with those numbers—an enormous impact on comprehensibility.

Remote collaboration. In addition to presenting data in three dimensions, spatial computing makes it possible for multiple people to interact with the same 3D dataset while in different physical environments. The implications for supply chain management or RCFA, for instance, are immediately obvious. Spatial computing makes it possible to collaborate in real time on your toughest challenges, no matter where your best minds are located.

Spatial computing will catapult Industry 4.0 forward

Today, AR is proving valuable in healthcare (for training surgeons, for example), education (especially to enhance remote training), and even navigation (as with the Google Maps app). And spatial computing is rising in popularity as more and more people recognize its ability to revolutionize data work.

In the manufacturing sector, savvy deployment of Industry 4.0 technologies is defining the manufacturing leaders of tomorrow and helping them pull away from last century’s titans. Spatial computing is yet another advancement that will let innovative manufacturing organizations sail ahead of the competition.

Whether you’re feeling ready to experiment with this newest technology or wondering how you can catch up, we’d love to talk.

If Industry 4.0 is new to you, the first step is often getting your data in order. In just two weeks, we can put together an assessment of your current data maturity and provide you with a roadmap of how to get to a point where you can use tech like spatial computing, internet of things (IoT), smart sensors, machine learning, and more to transform your organization.