Getting started with digital twins in manufacturing

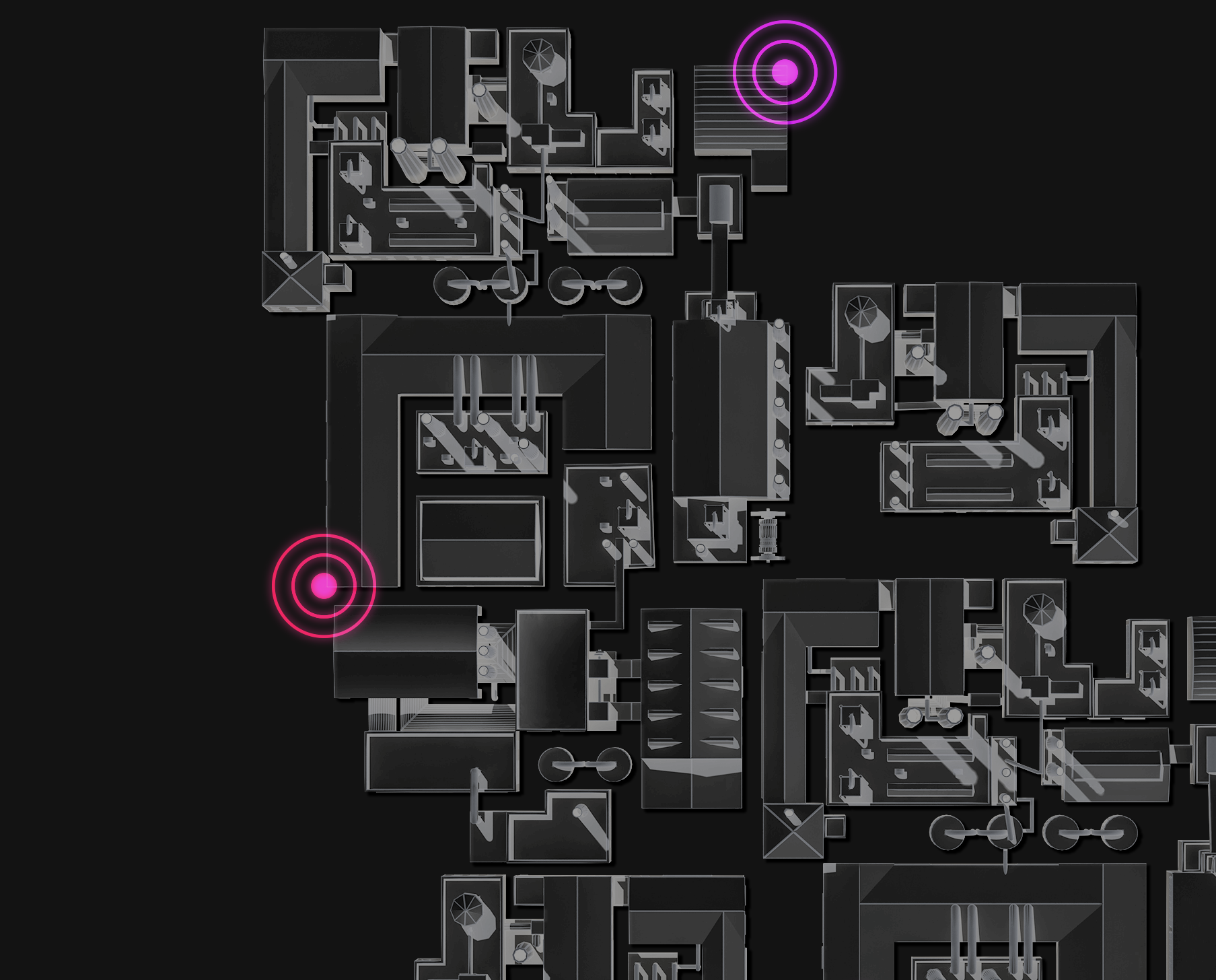

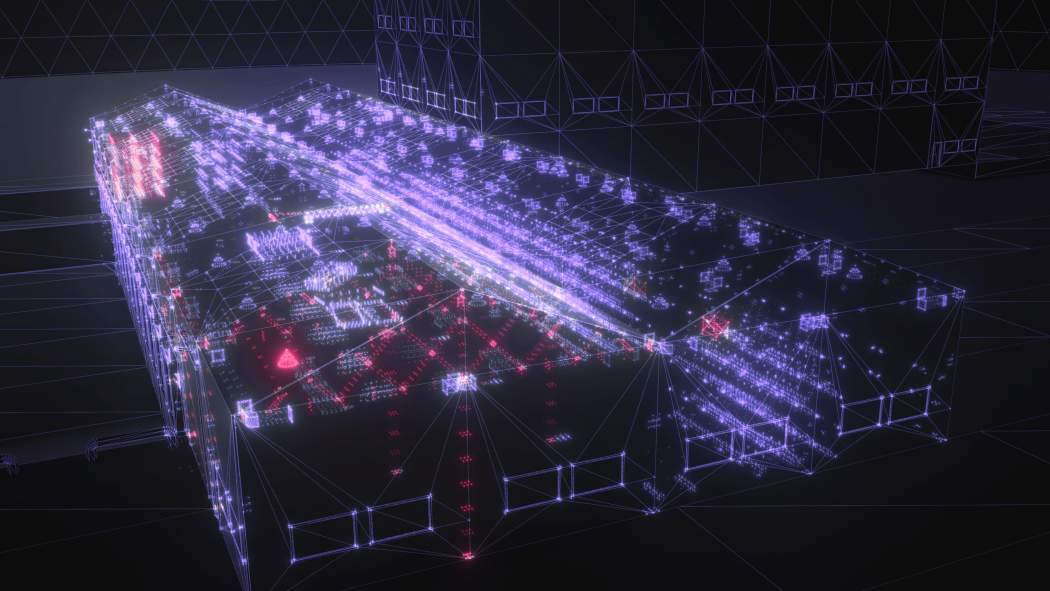

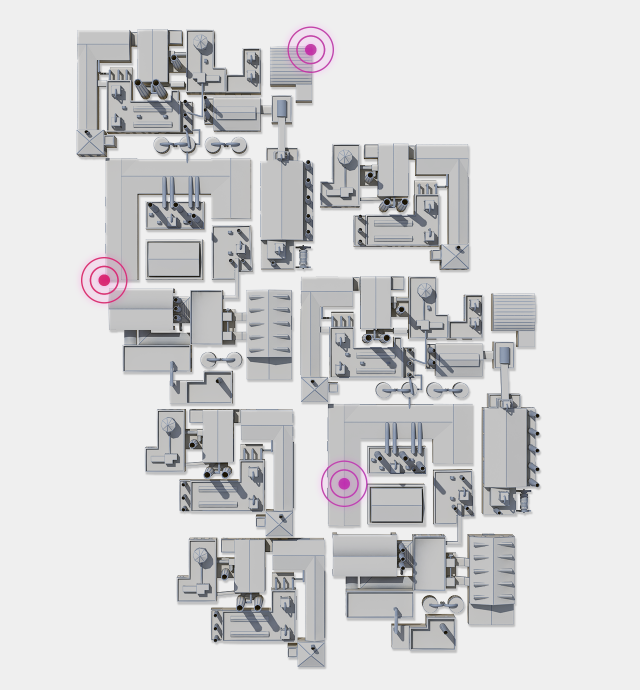

When a major storm is blowing into your region, you can track its progress—real and projected—on your favorite weather-tracking app. What if you had the same visibility into your facility’s production process? What if you could look at a screen and see real-time status of the factory floor, along with highly accurate forecasts?

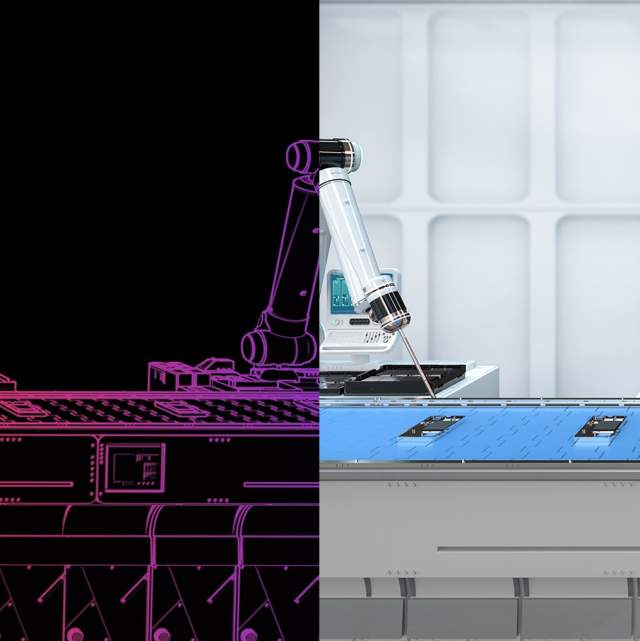

This isn’t a sci-fi thought experiment. That level of visibility is possible today, thanks to the capabilities of digital twins. Broadly, digital twins make it possible for manufacturers to use (rather than simply wrangle) the data produced by the organization.

When data is visualized in a meaningful way, manufacturing companies can glean data-driven insights, make informed decisions faster, and seize opportunities to stay ahead of their competition.

In this guide, we’ll explore what digital twins are, how they can advance manufacturing operations, and what you need to do to get your organization on the path to building and using a digital twin.