Digital Twin Accelerator

TXI’s Digital Twin Accelerator is a 2-week engagement designed to help mid-market companies quickly validate digital twin readiness.

Digital twins let you analyze, simulate, and optimize operations beyond the physical world, delivering enhanced visibility and efficiency. By testing adjustments virtually, you avoid costly mistakes in product development, assembly line changes, and supply chain planning, turning data into a powerful tool for innovation.

Our Digital Twin Accelerator is a low-risk entry point that helps operations managers, plant managers, and digital transformation leaders achieve quick wins while building a foundation for broader Industry 4.0 transformation.

Digital twins allow you to test and validate production changes virtually before implementation and enable real-time factory floor visibility to identify and resolve efficiency issues instantly.

Reduced mean time to repair

Enhanced maintenance efficiency

Improved asset utilization and performance

Decreased energy consumption

Enhanced quality control

Better inventory management

Our strategists partner with you to identify high-impact opportunities through hands-on observation of your operations and help sharpen and focus your idea while identifying the most effective ways to validate your assumptions, mitigate risks, and realize your ambitions.

Our data engineers assess your current data infrastructure and identify strategic opportunities for enhancement.

Our integrated team collaborates with you to identify the impact of a digital twin in your real-world conditions while uncovering opportunities to improve and optimize for your situation.

Our technical experts directly collaborate with your team to provide comprehensive support throughout the assessment.

We'll examine your current setup and create a step-by-step plan for success

We'll check your data and recommend ways to prepare it for a digital twin

We'll identify the most impactful improvements to make first

We'll create a growth plan that can expand as your needs do

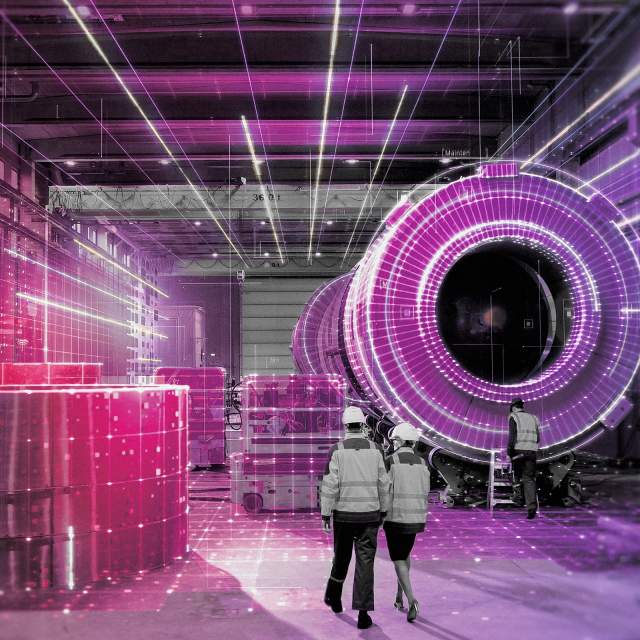

Your trusted partner in the Industry 4.0 revolution

TXI is a digital product consultancy with over 20 years of experience empowering mid-market companies to embrace smart factory solutions. We've established ourselves as a trusted partner in the Industry 4.0 revolution, helping companies leverage advanced technologies, including digital twins, AR/VR, cloud computing, data analytics, and artificial intelligence.

TXI helps mid-market visionaries confidently implement digital twin solutions through a proven, step-by-step approach that delivers quick wins while building toward comprehensive Industry 4.0 transformation.

From predictive maintenance to workflow automation, discover how manufacturers are transforming operations.

Modern Industrialist Podcast

Presented by TXI, The Modern Industrialist Podcast is for technology-focused manufacturing and logistics leaders looking to gain a competitive edge with Industry 4.0 transformation.

Join our host, Jason Hehman, as he brings together experts from companies paving the way for the IIoT revolution. Topics will range from advice to success stories, use cases, solutions, and more.

Partner with us to discover how digital twin technology can enhance your operational excellence, optimize costs, and drive innovation in your manufacturing operations.