The manufacturing industry is experiencing a profound transformation in how knowledge is acquired, shared, and applied. Traditional training programs, once the backbone of skill development, are rapidly becoming obsolete in an era of new technologies, automation, and digital transformation.

The challenges of analog training

Manufacturing training programs have long been a highly personalized, manual process with significant inherent limitations. Senior technicians have traditionally been the primary conduits of knowledge, spending countless hours away from production lines to train new staff. This approach creates multiple critical challenges for organizations.

The most pressing issue is the extreme vulnerability of institutional knowledge. When experienced manufacturing employees retire or change jobs, they take decades of specialized expertise with them. Training becomes a high-stakes game of knowledge transfer, where the loss of a single key individual can dramatically impact operational capabilities.

Moreover, the geographical and logistical constraints of traditional training methods severely limit scalability. A single senior technician can only train a small number of people simultaneously, creating bottlenecks in skill training and organizational growth.

Training Challenges:

Dependence on individual experts

Limited knowledge preservation

Geographic training constraints

Inconsistent skill transfer

High resource investment

The digital training advantage

Digital employee training platforms offer a revolutionary approach to addressing these fundamental challenges. By creating structured, accessible, and consistent learning environments, organizations can transform their approach to competency-based training and workforce development.

Modern digital training transcends traditional boundaries. Learners can access comprehensive online training materials from anywhere, at any time, eliminating geographical restrictions. These platforms provide a single source of truth, ensuring that every technician receives consistent, high-quality instruction regardless of location or timing.

The multimedia capabilities of digital training platforms represent a significant leap forward. Unlike traditional text-based materials, these platforms integrate videos, interactive simulations, and dynamic assessments that engage learners more effectively and comprehensively.

Key Digital Training Benefits:

Universal accessibility

Consistent knowledge transfer

Engaging multimedia content

Unlimited simultaneous learning

Comprehensive metrics for skill tracking

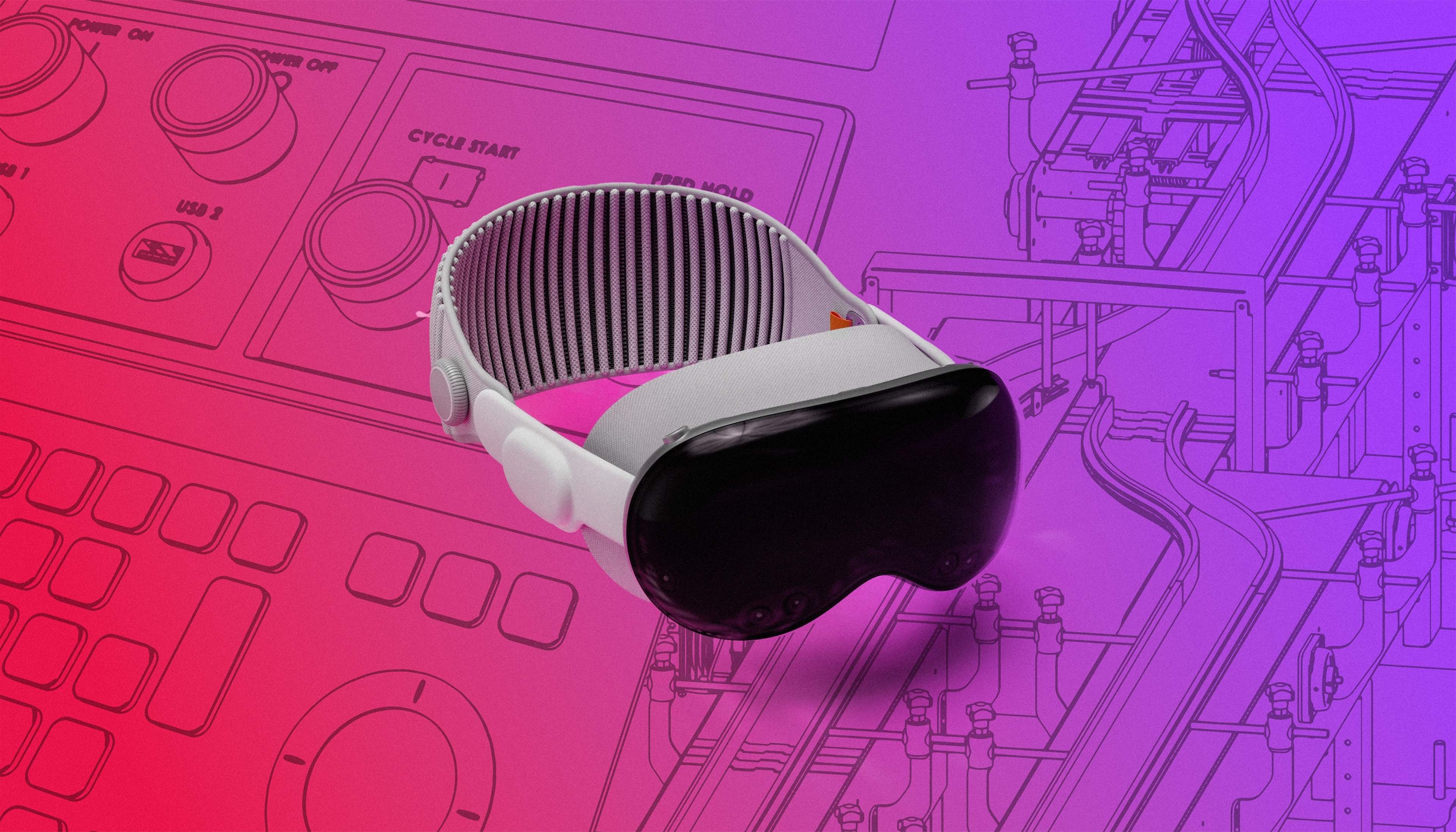

Immersive learning: The next technological frontier

Augmented Reality (AR) and Virtual Reality (VR) technologies are revolutionizing how manufacturing workers develop and practice technical skills. These hands-on training tools create precise digital replicas of complex manufacturing environments, allowing technicians to practice manufacturing processes without risking real-world equipment or production lines.

Immersive learning goes beyond simple observation. Technicians can actively perform procedures, repeat complex tasks, and receive immediate feedback in a risk-free environment. By repurposing existing CAD files and digital assets, manufacturing companies can create incredibly detailed and accurate training simulations.

The ability to practice without time or equipment constraints means technicians can develop muscle memory and confidence before engaging with actual machinery. This approach dramatically reduces onboarding time, minimizes potential errors, and accelerates competency-based skill acquisition.

Immersive Training Advantages:

Risk-free skill practice

Unlimited training repetitions

Precise equipment replication

Hands-on learning experiences

Reduced training-related downtime

AI-Powered personalization

Artificial intelligence is adding another layer of sophistication to manufacturing training programs. AI algorithms can now analyze individual learning patterns, identify specific skills training gaps, and generate personalized elearning experiences tailored to each technician's needs and expertise level.

These intelligent systems can adapt training content in real-time, ensuring that each learner receives the most appropriate and effective instruction. By tracking performance and understanding individual learning styles, AI creates a more responsive and efficient learning management system (LMS).

The future of training is not about delivering uniform content, but about creating dynamic, microlearning journeys that bridge the skills gap by recognizing the unique capabilities and potential of each individual.

The strategic path forward

Transforming manufacturing workforce training requires more than technological implementation. Organizations must develop comprehensive strategies that integrate digital tools into the work environment, create flexible learning infrastructures, and foster a culture of continuous improvement.

Strategic Transformation Steps:

Comprehensive digital asset inventory

Modular, adaptable training materials

Investment in immersive technologies

Cross-functional development teams

A culture of continuous learning and problem-solving

Ensuring workplace safety & compliance

Incorporating safety training into digital manufacturing training programs is critical for ensuring compliance with industry standards, such as OSHA regulations. Virtual training modules allow manufacturing employees to practice workplace safety protocols and emergency procedures in realistic environments before engaging in actual machine operation.

Additionally, AI-driven LMS platforms help track employee progress toward certifications, ensuring that workers meet necessary compliance standards. Regular audits can also be streamlined through digital training data, helping manufacturing facilities remain compliant and efficient.

Workplace safety enhancements:

OSHA-compliant safety protocols

Interactive safety training modules

AI-driven competency tracking

Simulated emergency response drills

Measuring effectiveness & continuous improvement

To maintain a competitive edge, manufacturing companies must measure the effectiveness of their training programs. Using training needs analysis, organizations can identify gaps and continuously refine skills training initiatives.

A well-designed learning management system enables organizations to track key metrics, such as:

Employee retention rates

Training completion percentages

Competency-based performance improvements

Reduction in workplace safety incidents

Quality control adherence and error reduction

By leveraging data-driven insights, organizations can optimize training programs to improve efficiency, ensure compliance, and maintain a skilled manufacturing workforce.

Future-proof your workforce

Digital and immersive training are no longer optional technologies—they are essential for staying competitive in the manufacturing sector. By embracing elearning, microlearning, and hands-on training, organizations can create more resilient, adaptable, and skilled workforces.

The future of manufacturing workforce development is interactive, personalized, and technology-driven. Those who recognize and act on this transformation will lead the next generation of manufacturing companies toward greater innovation and efficiency.

Curious about how to get started? Contact our team of consultants to learn more.